FAIST’s Rotary Electric Actuators productive plan, extending from 2020 to 2024, foresees various add productive lines being designed, integrated and constructed by FAIST to serve its automotive clients supplying them this new line of products. The fully automated lines will be set up in CPS&IND plants in North America, Europe and China.

We talked about these developments with Leonardo Laganà, Business Director of the Controls & Propulsion Systems business area.

"As always FAIST tries to stay as close as possible to the customer, in order to provide the best service minimizing the transit time to the client’s plants in different regions of the world. The introduction plan of our lines automotive E-actuators follows the customer-side introduction plan of OEM newest global platforms. The capacity increase plan, based upon our new automated lines, spreads out in three continents, North America, Europe, Asia, and with their SOPs within the next eighteen months.

Therefore, the production capacity over the next 20 months will be more than fivefold the current one; in fact, our advanced manufacturing engineering team is not only building the new productive lines, but also improving their design upon the experience made in the last five years.

Our final assembling capacity will be further increased in the following years, with plans that are still subject to tweaks and updates according to the customer’ needs and market demand.

In addition to these development activities focused on the final assembly lines, significant localization activities are also being carried out not only for the materials to be sourced from external suppliers, but also for the management of sub-components that will be produced internally by FAIST. Four new automatic lines for the production of the Body and Cover of the new REA actuators will be set up by 2022.”

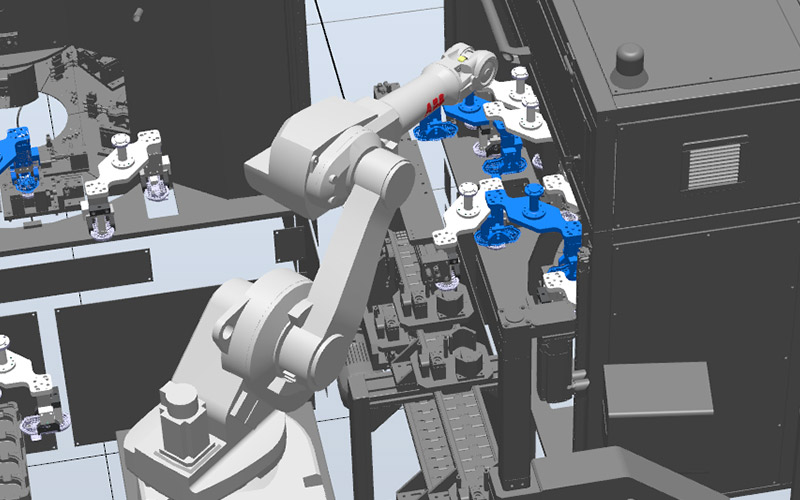

Jacopo Berlicchi, Advanced Manufacturing Engineering Manager told us that “the new lines are optimized for quick product changeover, increased productivity and they will be smaller in terms of shop floor that they occupy. Part of the design that has been previously done by subcontractors has been internalized in FAIST, such as the engineering of the automation, such as the pallet line that feeds the modules or the manipulations of the ABB robots. The overall cycle time has been reduced by re-engineering the single modules and changing some of their subcomponents and machineries.”

For FAIST CPS&IND human resources, this project has meant and will, in the years to come, need to be supported, by a strong development plan: the skills of our staff and its technical knowledge are being widened and deepened. But how is this practically translated to cover the needs of Manufacturing, Maintenance, Quality and Production teams? Lara Cerquiglini, head of corporate Human Resources for FAIST CPS&IND, believes that “to acquire and improve internally this type of skills, which were not a widely deployed background in our plants, is a strategic choice as much as an investment in these new projects. There are two main tasks, enhancing the already good skills our Manufacturing Eng. teams worldwide and making sure their knowledge is timely transferred to the Maintenance, Quality and Production teams. In doing so we are organizing external courses with specialized companies, wherever possible leveraging our partners know-how, and yet organizing dedicated cross-training session between employees. Obviously, the planning of these sessions dedicated to the people employed in the various plants of the different regions is consistent with our customers schedules."