Despite the growth of electric traction, the internal combustion engine will continue to exist as one of the main solution for car drivers in the next years. The restriction of emission limits for CO2 will continue to lead the investments and choices of the automotive industry, in order to put on the market models compliant with the WLPT (World Harmonized Light Vehicle Test Procedure) homologation cycle introduced in 2018. Consequently, the use of turbo systems in cars is expected to rise in the next years as the main solution to increase the performance and reduce the fuel consumption of the engine.

The turbo technology was initially born to increase the performance of diesel engines because they have lower power compared to gasoline ones considering the same displacement. During the years, turbo systems became one of the many solutions for carmakers to reduce the size of the engine: the compressor side of the turbo increases the fill ratio of the cylinder and in this way, it is possible to reduce the fuel consumption, with the obvious improvement in terms of CO2 and NOx emission.

The wastegate valve of the turbo, closed when the turbo is in function and open when the pressure is too high, guarantees the safeguard of the system and is moved by an actuator. In the market there is a widespread use of pneumatic actuators for wastegate applications, but in order to guarantee the controllability of the position the WG valve has in each position of its stroke, a continuous communication between the actuator and the ECU is necessary: this is the main reason why electric actuators are replacing the pneumatic ones.

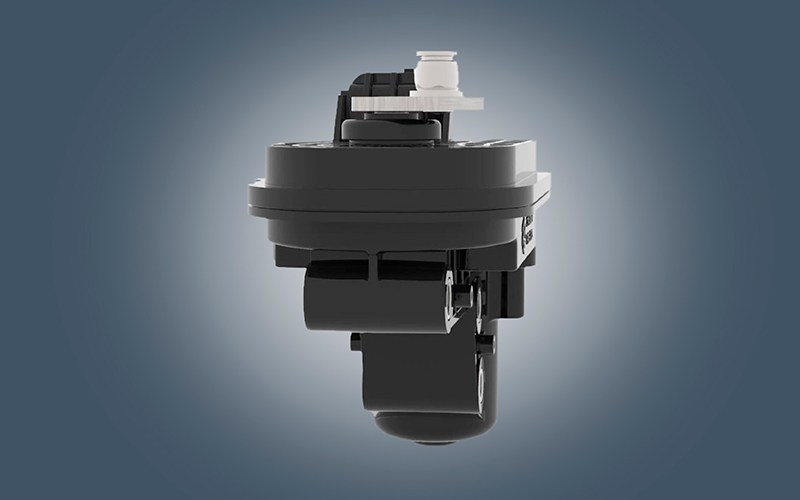

FAIST’s portfolio of rotary electric actuator includes REA-WGs, a wide range of products developed by FAIST’s R&D department with specific characteristics aimed at guaranteeing controllability and functionality, suiting most wastegate applications in the market.

To continue our review of FAIST’s electronic actuation, we asked Valentina Pannaioli, Program Manager for REA-WGs, to tell us why she is proud to promote these products in the market. Here is what she has to say:

FAIST has developed actuators completely made in plastic materials and also a model using a combination of plastic and aluminum. All products passed the required mechanical and environmental tests to simulate all the extreme conditions in which the product will operate in the car. The different type of water tests done have highlighted one of the strengths of our products: the sealing. No water penetration was found in any REA-WGs sample tested! All products are compliant to the EMC standards for electromagnetic noise regulation and can work in the range of temperature of -40°C to 160°C.

FAIST has designed and validated also the majority of subcomponents, starting from the design, choice of the material and tooling design, with a direct control in the production process. Thanks to our know-how, we can customize a great part of the actuator interfaces such as fixing points, crank pins, connector orientation and shape – these can all be adapted to the needs of the specific client application for each size of REA-WGs.

The smallest actuator in the REA-WGs range is REA-S, measuring 65X92mm and 125,7mm in height. Although small, it has a remarkable holding torque of 226Ncm measured at 160°C. With its compact packaging and outstanding performance characteristics, it can fit onto most applications in the market. For higher torque requirements FAIST developed the REA-XL, which has an holding torque up to 300Ncm at 160°C, in a slightly bigger packaging of 75X97x140mm, made of a combination of plastic and aluminum, necessary to guarantee a high performance level. Our third model, REA-L, was designed as an intermediate solution between REA-S and REA-XL in order to cover also this area in the market.

Even though the products previously described are already validated, our R&D team keeps studying new solutions to improve the assembly design and the design of each subcomponent, in order to continuously optimize the existing performance of FAIST’s REA-WGs.

FAIST has the possibility to produce the wastegate actuators all over the world, with our production locations in Asia, Europe and North America, in order to support in the best possible way our customers.