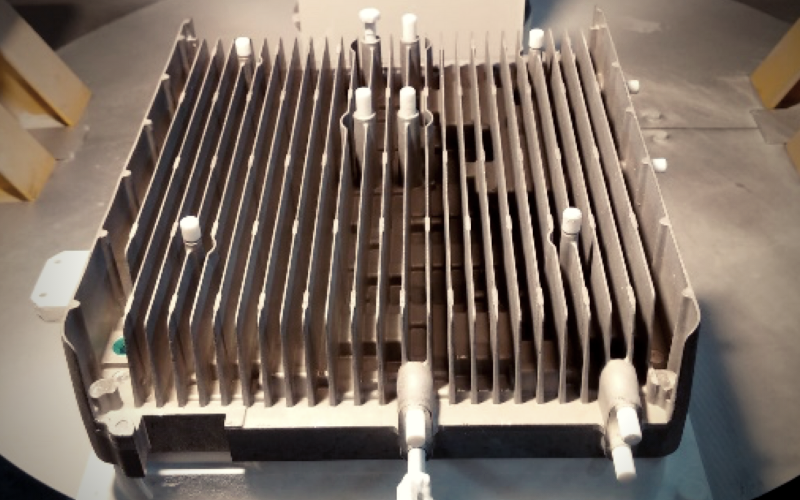

After implementing the anodizing process for automotive at the beginning of the year, our engineers in Faist Light Metals took on the challenge to create a powder coating line for telecom parts.

The need to find a new solution to satisfy our customers become more and more stringent as we wanted to offer all the services together to having both the capability and the flexibility requested by the client to produce at the highest standards.

After a detailed research, our team came to the conclusion that the best solution was to open the powder coating line and paint the parts in house.

In order to provide better products, our engineers decided to implement a line that is better than any powder coating line available on the market, eliminating some human error, associated with manual processes, ensuring that a uniform coating layer is applied on the whole surface of the parts. The rules of powder coating were reimagined: our painting gun was placed on a robotic arm, which is moving around the parts placed on the fixture. The automatization guarantees the repeatability and high stability of the process.

The project started at the beginning of this year when the powder coating cell and the polymerizing oven were built. In a short time the team managed to run the first test trial with positive results.

After obtaining the first coated parts, a period of fine tuning followed. The challenges that needed to be solved were:

-

Ensure that the program is fully capable of covering the parts 100%

-

Find a way of masking and handling the parts in order to keep the covered parts untouched

-

Find a solution to spray the powder in a constant way in order to have the same thickness of powder on the entire part

-

Find a solution to have the parts covered perfectly especially on the machined area

-

Adjust the polymerizing oven parameters to make sure that the painted parts will pass the crosshatch and corrosion tests

After finding solutions for all the challenges we faced, our team obtained the approval of our customers to paint the parts in-house. The whole implementation and testing process lasted for 6 months and we are very proud to announce that the first approved delivery of in house painted parts will be delivered to our customers this month.

Well done!