In the last years FAIST Controls and Propulsion Systems Division developed a group of new products for the automotive market, increasing the production capacity in several departments with new lines, machines and equipment.

Massimo Mattoli, the Chief Operating Officer of the divisions Controls & Propulsion Systems and Industrial, gave us his perspective on these developments. Having been in this role for over 10 years, overseeing Operations across the 5 facilities located on 3 continents, Mr. Mattoli has experienced first-hand the challenges and successes of these new progresses of FAIST.

Faist Controls and Propulsion Systems Division is a leader in the development and industrialization of mechanical components for the automotive sector; currently, our flagship products are electromechanical actuation systems, primarily used in turbocharger control systems. However, these systems are also finding widespread use in applications related to electric vehicles, including parking lock systems, charging gate systems, and thermal management control.

Within this division, there are four facilities involved: Faist Componenti and Faist Romania in Europe, Faist Emission Controls in China, and Faist MetalMex in Mexico.

These facilities are involved both in the production of subcomponents used within the electric actuators and in the final assembly of the actuators themselves.

In recent years, Faist has won numerous projects with these products, covering many of the new platforms of well-known OEMs. Implementing these projects across multiple facilities on three continents required significant financial and organizational effort.

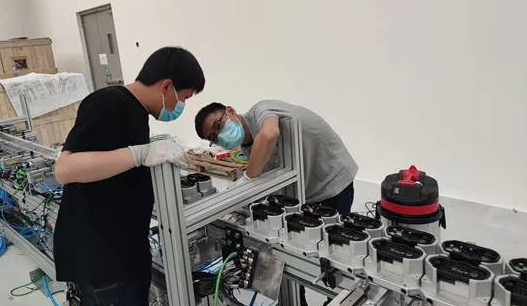

This introduction plan has been initiated and is still ongoing. It has been a challenging plan, especially considering that the start of various installations coincided with the start of the pandemic. The first lines developed and installed were the plastic and steel subcomponents production lines at the Montone plant in 2019. Subsequently, assembly lines were installed in Romania in 2021, and in China and Mexico in 2022. Currently, the team is working to increase the production capacity of the actuators in Italy and China, as well as to localize various subcomponents. This plan includes further investments and installations in China and Mexico by the end of 2024. Additional lines are already in the planning stages with FAIST’s Manufacturing team, to further expand capacity in extra-European facilities.

The developed production lines are highly flexible, allowing FAIST CPS to produce all current projects and to balance customer demands among various facilities. This also enables us to make the necessary adjustments in case of technical issues and to support emergency plans.

The overall plan aims to achieve a capacity of 6.5 million pieces. Currently, in 2023, the production is expected to reach 1.05 million electric actuators, primarily using the Chinese and Romanian facilities. In 2024, production is projected to reach 2.35 million actuators, involving the Mexican plant as well. Subsequently, there is a steady growth plan of approximately 1.2-1.5 million units per year to reach 6.5 million by 2027, involving all facilities, including the Italian one.

Switching from the well-established production lines of pneumatic actuators, developing a completely new product, added to the challenges related to highly automated production lines with multi-plant installations worldwide, all during the COVID-19 pandemic period, has not been easy. The challenges included adapting the skills of operators, maintenance, and quality control. All of this occurred while we experienced significant material shortages, including components, chips, and plastic materials, due to the pandemic, as well as significant travel restrictions that complicated installations, especially in China.

FAIST Controls and Propulsion Systems is proud and grateful for the trust of our clients that has enabled our growth. Together, we have faced this significant challenge and expanded our product portfolio. Despite the difficulties, the dedication of our teams and the support of our clients have driven us forward. We are excited to continue this journey with our clients toward a future full of opportunities. The projects we've won and our future plans attest to the strength of our partnerships, allowing us to look ahead with pride, eagerly awaiting the next chapters of growth and innovation.