FAIST Light Metals Engineering is constantly looking for new strategies to improve the efficiency of its processes and reduce “muda”.

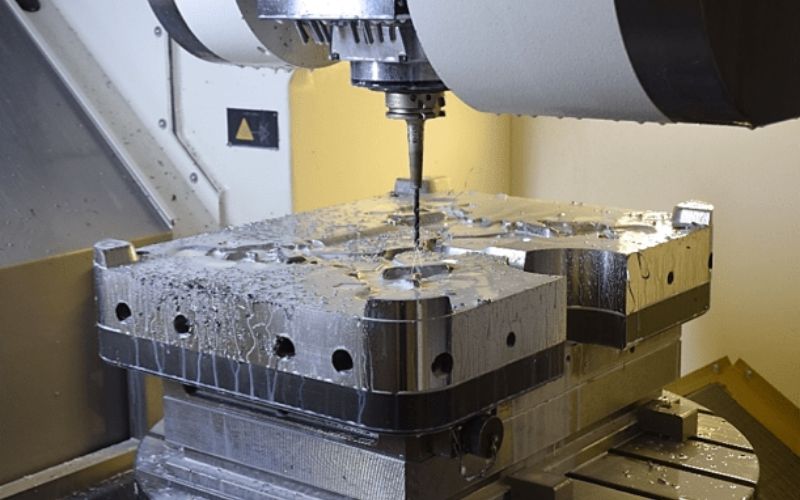

From the analysis carried out in the last months we identified potential improvement in the CNC department.

Nowadays, machining processes must be pushed to maximum efficiency, optimizing cutting tool life and at the same time ensuring high quality of the die casting tools.

For this reason, we looked for a supplier to share our needs and objectives.

The challenge was accepted by a leading company in the production of high-performance cutting tools for moulding. We have undertaken a partnership with them destinated to last in time.

The sharing of experience of the partner about tool-paths strategies and the choice of the technological parameters combined with the specific know-how of FLME in the die casting moulds manufacturing, has created a successful synergy that led to excellent results, sometimes exceeding our expectations.

The first tests were carried out on the mobile and fixed matrices of Integral Heatsink, one of the main products for our Ericsson’s customer.

Our approach to milling has changed considerably, we have reduced errors and reworkings, optimized strategies and standardized technological parameters recovering efficiency in non-performing processes.

We are looking forward to extending this activity to other die casting tool’s types.