Global warming is an increasingly urgent issue: some of the latest research says if we want to keep the Earth’s climate within the range humans have experienced, we must act now, otherwise we could push the climate beyond tipping points, where the situation spirals out of our control.

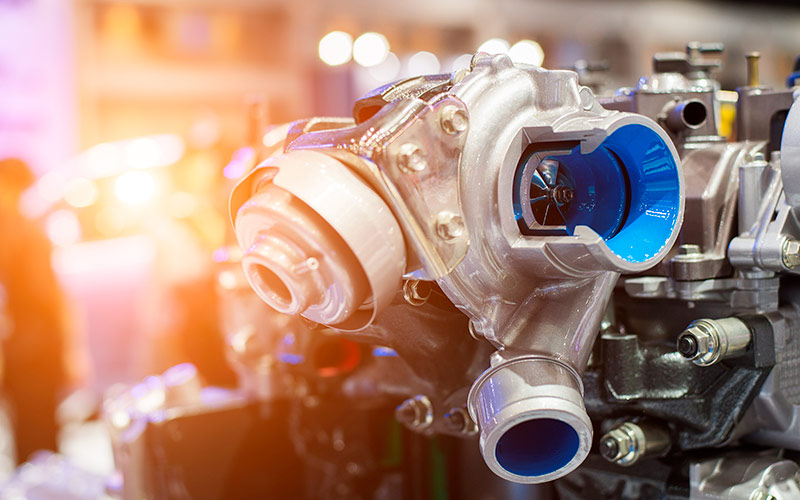

One of the aspects that we need to tackle is indeed the emissions of the global vehicles fleet. Turbochargers have an important role to play in the area of reducing fuel consumption and CO2 emissions. On the basis that emissions regulations are becoming tougher and tougher, it is inevitable that demand for turbochargers will rise, and their technological load increase. In fact, turbos are now seen as essential in meeting CO2 emissions. The emissions rules that are being applied across the world require increasingly sophisticated engine and exhaust management systems to ensure that vehicles comply with these standards. As with other automotive technologies, one of the solutions is electronic control. The addition of electronic controls to turbochargers is typical of what has happened to other areas of the car: the application of electronics to mechanical parts.

Managing the complex interactions between turbochargers, exhaust gas recirculation equipment and other related engine components is not straightforward and the development of appropriate controls has been a slow and iterative process.

One of the first areas of gasoline engines turbochargers to become electronically controlled has been the waste gate. Originally, it was pneumatically controlled, but electronic control of its actuation allows the improvement of fuel consumption, thanks to the reduction of exhaust backpressure; a decrement in the time required for catalysts to become operational; and improved traction control, as electronic control of the waste gate better regulates the amount of torque that reaches the vehicle’s driven wheels.

FAIST’s Controls & Propulsion Systems team has been working for years to provide our clients the best possible solutions in this field, developing a range of pneumatic, sensor controlled and electric actuators that fit most engine applications from a technological and performance perspective, are highly customizable, and extremely reliable. Our extensive work is now paying off – we have been awarded with many major projects, and our electric actuators will fit onto the turbochargers of premium players in the automotive industry. A great way to end FAIST’s year, and to start 2020 on a high note.